Specialty Lubrication

Lubrication

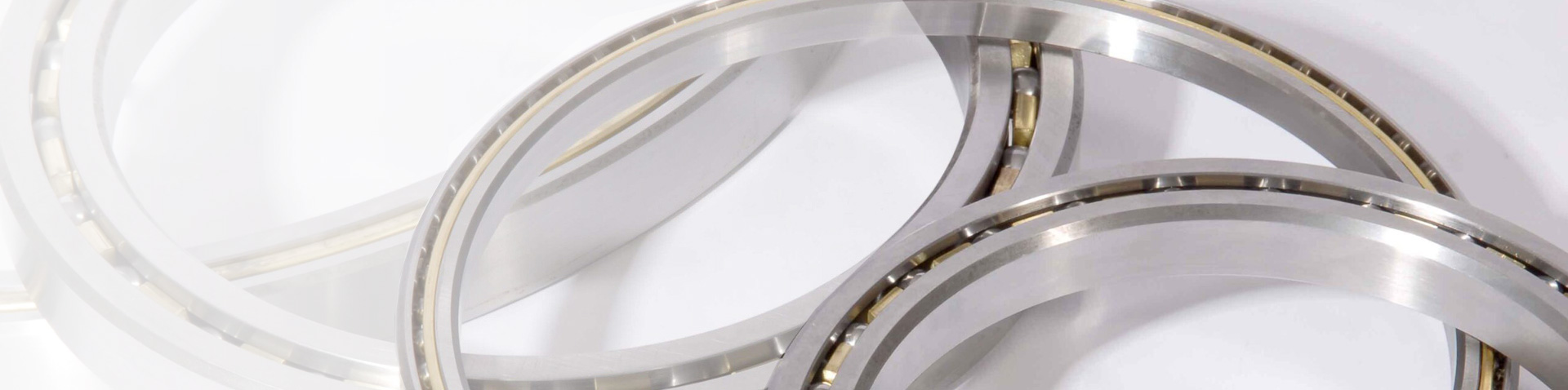

At Silverthin, our expertise in specialty lubricants ensures your thin section bearings and slewing rings operate at their peak.

Lubricant Selection Process

Our Lubrication Selection Process includes:

- Operating Temperature: Determining the temperature ranges your bearings will be exposed to.

- Viscosity Dynamics: Ensuring consistent viscosity across all operating temperatures.

- Operating Speeds: Catering to both continuous and oscillatory motions.

- Friction Torque Requirements: Balancing the need for speed with energy efficiency.

- Lubricant Migration Control: Ensuring consistent lubrication coverage.

- Operating Loads: Addressing both dynamic and static loads.

- Material Compatibility: Ensuring the lubricant complements the bearing materials.

- Corrosion Protection: Protecting your bearings from environmental challenges.

- Volatility & Outgassing Tolerance: Ensuring lubricant stability under different conditions.

- Shelf Life: Ensuring the lubricant’s longevity matches your operational needs.

Tailored Lubrication Solutions for Your Application

- Thin Section Bearing Lubrication: Reliance on ball and raceway surface lubrication is crucial. Our standard open bearings are shipped with a light corrosion-inhibiting oil, it’s essential to further lubricate them per your application’s specifics. Sealed bearings, on the other hand, come with a 20%-30% fill of MilG-81322 grease.

- Slewing Ring Lubrication: The robust world of slewing rings typically depends on grease for optimal performance. Regular lubrication through provided channels is paramount for these bearings.

Diverse Lubrication Methods for Optimal Results

- Oil Lubrication: Options include Dip & Drain, Dip & Centrifuge, Vacuum Impregnate, Metered Application, and Film Oiling.

- Grease Lubrication: Methods range from Standard Greasing and Film Greasing to Grease Plating.

- Solid-Film Lubrication: For specific applications requiring solid-film solutions, please consult with Silverthin Engineering.